| Description: |

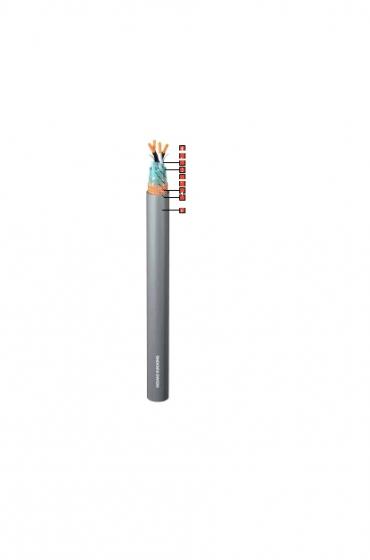

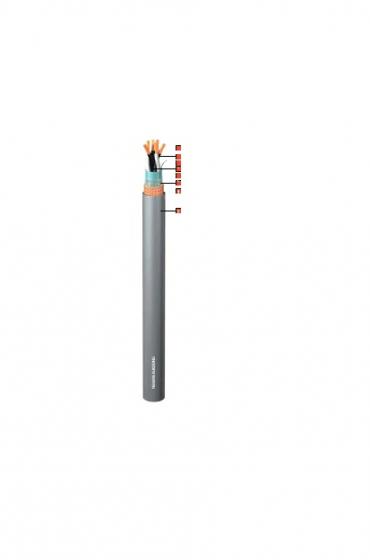

250V BFOU(I)

Application

Construction Details

1) Conductor : Circular tinned stranded copper wires as per IEC 60228 Class 2

2) Insulation : Mica tape and Halogen-free Ethylene propylene rubber (HF-EPR) as per IEC 60092-351

3) Pair / triple twisting : Two / three insulated cores twisted together with suitable lay length

4) Individual screening : Wrapped by copper or aluminium backed polyester tape with tinned copper drain wire

5) Core assembly : Screened pairs / triples are laid up with non-hygroscopic fillers and the binder tape may be applicable

6) Bedding : Halogen-free compound (inner covering)

7) Armour : Copper wire braid as per IEC 60092-353

8) Outer Sheath

- Halogen-free thermoset compound as per IEC 60092-359, SHF2

BFCU(I) = with galvanized steel wire braid

- Code-S3 : Halogen-free thermosetting compound as per IEC 60092-359, SHF2

- Code-S3/S7 : Halogen-free & Mud resistance thermosetting compound as per IEC 60092-359, SHF Mud

Standards Applied

· Design guideline : IEC 60092-3/ 353 / 375

· Material properties : IEC 60092-351 (Insulation, HF-EPR)

IEC 60092-359 (Sheath, SHF2)

|