Application

- Power circuit below 1 KV

- Fixed installation in both explosion risk and safe areas.

- Medium voltage power cables for emergency and critical systems.

- Maximum operating conductor temperature 90 °C

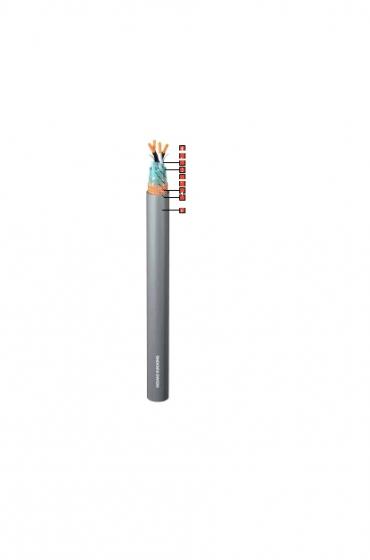

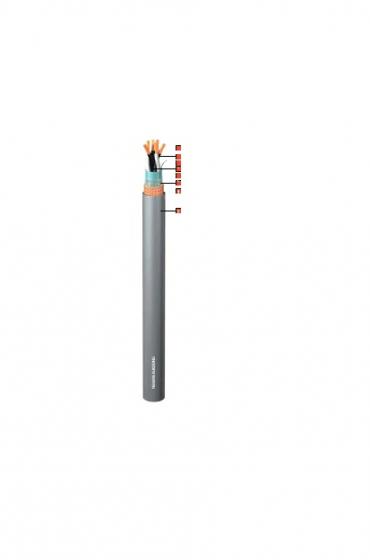

Construction Details

1) Conductor : Circular tinned stranded copper as per IEC 60228 & 60228 A, Class 2

2) Conductor screen : Semi-conducting tape

3) Fire proof layer : Mica glass tape

4) Insulation : Halogen Free Ethylene Propylene Rubber (HF-EPR) as per IEC 60092-351, type “HF EPR”

5) Insulation screen : Semi-conducting compound and Semi-conducting tape

6) Metallic screen : Copper (annealed or tinned) wires braid as per IEC 60092-354

7) Cabling (with filler, binder tapes over the assembly of laid-up cores)

8) Sheath : Flame retardant, Halogen-free thermosetting compound as per IEC 60092-359, SHF 2

9) Armour : (Copper wires braid (screen) as per IEC 60092-353/350

-RFCU (option) : Galvanized steel wire braid as per IEC 60092-353/350

10) Sheath : Flame retardant, oil, abrasion, chemical and sunlight resistant.

- Code-P6 : Halogen-free thermosetting compound as per IEC 60092-359, SHF2

- Code-P6/P13 : Halogen-free & Mud resistance thermosetting compound as per IEC 60092-359, SHF Mud.

Standards Applied

· Design guideline : IEC 60092-3 / 353

· Material properties : IEC 60092-351, Insulation, EPR’

IEC 60092-359, Sheath, XLPO, type ‘SHF2’

- Flame retardant : IEC 60332-3, Cat. ‘A’

- Fire Resistant : IEC 60331

- HCL emission : IEC 60754-1, 0.5%

- Low Smoke properties : IEC 61034-1/2

- Oxygen index (option) : ASTM D 2863, 32

- Cold properties (option) : CSA C22.2 No. 03

- Sunlight resistance : UL 1581

- Mud resistance (option) : NEk 606-2004 3’rd ed

- Mineral Oil-IRM 903 (option) : NEk 606-2004 3’rd ed